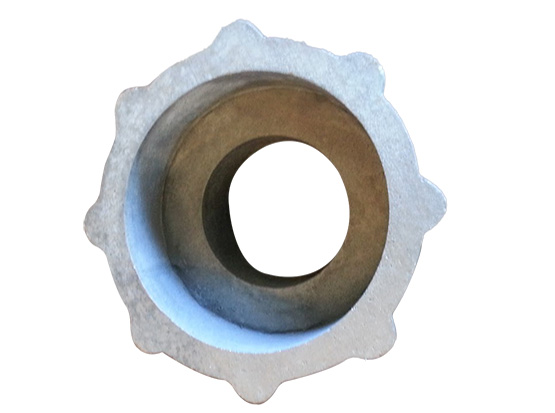

Sand casting

Sand casting foundry

Sand casting process uses the green sand or dry sand to make the molds for casting molten metals. Most of castings are produced by this old but new casting process. Sand casting is one of the most popular and simplest types of casting. Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost.

Due to its well-suited for complex geometries, sand casting process takes advantage of compact sand, refractory and recyclability to produce relatively less expensive molds with quick tooling development and design changes at a competitive cost. For some desired castings of huge size and weight, the sand casting process is the first choice we should think when we choose the suitable manufacturing methods.

In our high-tech facilities, we offer both automatic machine and manual molding operations in our resin sand casting processes. We can pour gray and ductile iron castings using our no-bake process up to 1 ton finished weight in gray iron castings and ductile iron castings, and up to 0.5 tons in steel castings.

|

Description |

Molding by hand |

Molding by Automatic Machines |

|

Max size of Castings |

1,500 mm × 1000 mm × 500 mm |

1,000 mm × 800 mm × 500 mm |

|

Casting Weight Range |

0.5 kg - 1,000 kg |

0.5 kg - 500 kg |

|

Annual Capacity |

4,000 tons - 5,000 tons |

5,000 tons - 7,000 tons |

|

Casting Tolerance |

On Request or Standard (ISO8062-2013 or GB/T 6414-1999) |

|

|

Molding Materials |

Green Sand, Resin Coated Sand |

|

|

Casting Metal & Alloys |

Gray Iron, Ductile Iron, Carbon Steel, Alloy Steel, Stainless, Al Alloys, Brass...etc. |

|

- Gray Cast Iron: HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30,GG35, GG40.

- Ductile Cast Iron (Nodular Cast Iron): GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-40-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN-GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- White iron, compacted graphite iron and malleable iron.

- Malleable Cast Iron

- Carbon Steel, Alloy Steel

- Aluminiumand Its Alloys

- Brass and Copper-based Alloys

- Stainless Steel / Duplex Stainless Steel

- Other Alloys as request or according to ASTM, SAE, AISI, GOST, DIN, EN, ISO, and GB.

Custom Sand Castings we are casting

|

|