The Pessimist is personified by my husband. Whenever he gets the smallest bit of bad news he immediately leaps.

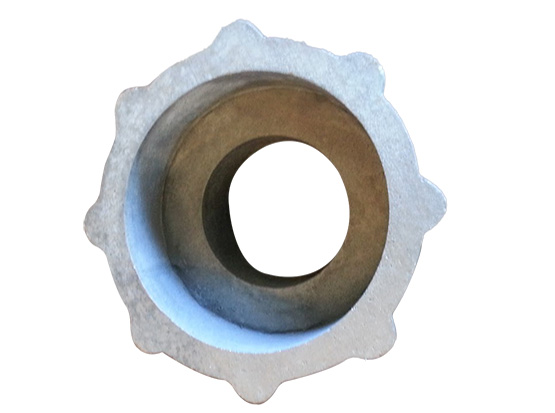

What we can achieve by sand casting

|

Description |

Molding by hand |

Molding by Auto Machines |

|

Max size of casting |

1500mmx1000x500mm |

1000mm x 800mm x 500mm |

|

Casting weight |

0.5kg to 1,000kg |

0.5kg to 1,000kg |

|

Annual Capacity |

3,000 tons to 5,000 tons |

6,000 tons to 8,000 tons |

|

Casting tolerance |

On request or standards |

|

|

Molding Materials |

Green sands, resin coated sands |

|

|

Casting metal& Alloys |

Grey iron, Ductile iron, carton steel Alloy steel,Brass…. |

|

Step of sand casting Process

- Making pattern

Patterns made of goods, resin(plastics) or Aluminum can be used to produce during casting. But the Aluminum costs will be the highest and will be the most suitable process if you need thousands of castings with high dimensional tolerances and better surface quality.

- Molding process

The resin sand will be mixed by the sand treatment equipment, then shoot into the sand boxes. The molding workers will guarantee the sand can be filled to all positions, then make the sand as solid as possible.

- Self-hardening

After molding by workers, sand is still loose, then sand mold will be coated by a type of alcoholds based coating, after burning, the resin sand mold will become solid. This is why casting process is called as hard hold casting process.

- Melting and pouring

Just like sand casting process, medium frequency electrical furnaces are used to melt iron for sanding casting process.

- Sand blasting, cleaning and grinding

The shot blasting process is to remove the sand, oxides… then workers will cut of the gating systems, grind the gating and parting lines. Finally, the rough castings will be completed.

If the 2nd processes like machining are needed, these complete castings will be taken to the next steps.

Sand casting foundry

Sand casting process uses the green sand or dry sand to make the molds for casting molten metals. Most of castings are produced by this old but new casting process. Sand casting is one of the most popular and simplest types of casting. Sand casting allows for smaller batches than permanent mold casting and at a very reasonable cost.

Due to its well-suited for complex geometries, sand casting process takes advantage of compact sand, refractory and recyclability to produce relatively less expensive molds with quick tooling development and design changes at a competitive cost. For some desired castings of huge size and weight, the sand casting process is the first choice we should think when we choose the suitable manufacturing methods.

In our high-tech facilities, we offer both automatic machine and manual molding operations in our resin sand casting processes. We can pour gray and ductile iron castings using our no-bake process up to 1 ton finished weight in gray iron castings and ductile iron castings, and up to 0.5 tons in steel castings.

|

Description |

Molding by hand |

Molding by Automatic Machines |

|

Max size of Castings |

1,500 mm × 1000 mm × 500 mm |

1,000 mm × 800 mm × 500 mm |

|

Casting Weight Range |

0.5 kg - 1,000 kg |

0.5 kg - 500 kg |

|

Annual Capacity |

4,000 tons - 5,000 tons |

5,000 tons - 7,000 tons |

|

Casting Tolerance |

On Request or Standard (ISO8062-2013 or GB/T 6414-1999) |

|

|

Molding Materials |

Green Sand, Resin Coated Sand |

|

|

Casting Metal & Alloys |

Gray Iron, Ductile Iron, Carbon Steel, Alloy Steel, Stainless, Al Alloys, Brass...etc. |

|

- Gray Cast Iron: HT150, HT200, HT250, HT300, HT350; EN-GJL-100, EN-GJL-150, EN-GJL-200, EN-GJL-250, EN-GJL-300, EN-GJL-350; GG10, GG15, GG20, GG25, GG30,GG35, GG40.

- Ductile Cast Iron (Nodular Cast Iron): GGG40, GGG45, GGG50, GGG60, GGG70, GGG80; EN-GJS-400-18, EN-GJS-40-15, EN-GJS-450-10, EN-GJS-500-7, EN-GJS-600-3, EN-GJS-700-2, EN-GJS-800-2; QT400-18, QT450-10, QT500-7, QT600-3, QT700-2, QT800-2;

- White iron, compacted graphite iron and malleable iron.

- Malleable Cast Iron

- Carbon Steel, Alloy Steel

- Aluminiumand Its Alloys

- Brass and Copper-based Alloys

- Stainless Steel / Duplex Stainless Steel

- Other Alloys as request or according to ASTM, SAE, AISI, GOST, DIN, EN, ISO, and GB.

Custom Sand Castings we are casting

|

|

EHT Company cooperate together with my local foundries in Hai Phong city which have high abilities doing steel casting and offering the investment casting (lost wax casting) possibilities with best quality casting parts for competitive prices to to produce various steel castings parts for our clients. These are widely appreciated by our clients for their strength, durability and corrosion resistance. We can provide these in customized sizes and specifications in accordance with the requirements of our esteemed clients.

The materials include low mild carbon steel, medium carbon steel, high carbon steel, low alloy, alloy steels. Production as standards AS2074, ASTM A148, A128, A128M, A297, KS D4101, AISI 410, 416..

Structural Characteristics of Alloy Steel Castings

The minimum wall thickness of steel castings should be greater than the minimum wall thickness of gray cast iron. It is not suitable to design too complex castings

* Steel castings have relatively large internal stress and are easy to bend and deform

* The structure should minimize hot nodes and conditions for sequential solidification should be created

* The fillet of the connecting wall and the transition section of different thickness are larger than those of cast iron

* Complicated castings can be designed into a casting + welding structure to facilitate casting production

Please contact us for more details: This email address is being protected from spambots. You need JavaScript enabled to view it.

We will feedback to you within a business day.

|

|

Below are carbon Structural Steel Grades:

|

GB |

ASTM |

BS |

JIS |

NF |

DIN |

|

08F |

1006 |

040A04 |

S09CK |

|

C10 |

|

08 |

1008 |

045M10 |

S9CK |

|

C10 |

|

10F |

1010 |

040A10 |

|

XC10 |

|

|

10 |

1010,1012 |

045M10 |

S10C |

XC10 |

C10,CK10 |

|

15 |

1015 |

095M15 |

S15C |

XC12 |

C15,CK15 |

|

20 |

1020 |

050A20 |

S20C |

XC18 |

C22,CK22 |

|

25 |

1025 |

|

S25C |

|

CK25 |

|

30 |

1030 |

060A30 |

S30C |

XC32 |

|

|

35 |

1035 |

060A35 |

S35C |

XC38TS |

C35,CK35 |

|

40 |

1040 |

080A40 |

S40C |

XC38H1 |

|

|

45 |

1045 |

080M46 |

S45C |

XC45 |

C45,CK45 |

|

50 |

1050 |

060A52 |

S50C |

XC48TS |

CK53 |

|

55 |

1055 |

070M55 |

S55C |

XC55 |

|

|

60 |

1060 |

080A62 |

S58C |

XC55 |

C60,CK60 |

|

15Mn |

1016,1115 |

080A17 |

SB46 |

XC12 |

14Mn4 |

|

20Mn |

1021,1022 |

080A20 |

|

XC18 |

|

|

30Mn |

1030,1033 |

080A32 |

S30C |

XC32 |

|

|

40Mn |

1036,1040 |

080A40 |

S40C |

40M5 |

40Mn4 |

|

45Mn |

1043,1045 |

080A47 |

S45C |

|

|

|

50Mn |

1050,1052 |

030A52 |

S53C |

XC48 |

|