Gray Iron Casting in viet nam

EHT Foundry, a Viet Nam iron foundry, is producing various gray iron casting parts for overseas clients in USA, Australia, Germany, Japan.

Production according to standards ASTM A48, A536; DIN 1691, 1693; ISO 185, 1083; EN 1561, 1563; DIN 1691, 1693; AS 1830, 1831; JIS, UNI, NF, BS, UNF, NBN, AS, SS, NS.

The main products include cast iron foundation plates, manhole covers, cast iron cook wares, stove burners, stove grill, grates, counter weight, crane balls, pump bodies etc.

The following is the material grade comparison table for gray cast iron in all countries.

|

Country |

Standard |

Equivalent Grades of Grey Iron (Gray Cast Iron) |

||||||

|

ISO |

ISO 185 |

100 |

150 |

200 |

250 |

300 |

350 |

- |

|

China |

GB 9439 |

HT100 |

HT150 |

HT200 |

HT250 |

HT300 |

HT350 |

- |

|

USA |

ASTM A48 |

- |

NO.20 |

NO.30 |

NO.35 |

NO.40 |

NO.50 |

NO.55 |

|

Germany |

DIN 1691 |

GG10 |

GG15 |

GG20 |

GG25 |

GG30 |

GG35 |

GG40 |

|

European |

EN 1561 |

EN-GJL-100 |

EN-GJL-150 |

EN-GJL-200 |

EN-GJL-250 |

EN-GJL-300 |

EN-GJL-350 |

|

|

Japan |

JIS G5501 |

FC100 |

FC150 |

FC200 |

FC250 |

FC300 |

FC350 |

- |

|

Italy |

UNI 5007 |

G10 |

G15 |

G20 |

G25 |

G30 |

G35 |

- |

|

France |

NF A32-101 |

- |

FGL150 |

FGL200 |

FGL250 |

FGL300 |

FGL350 |

FGL400 |

|

UK |

BS 1452 |

100 |

150 |

200 |

250 |

300 |

350 |

- |

|

India |

IS 210 |

- |

FG150 |

FG200 |

FG260 |

FG300 |

FG350 |

FG400 |

|

Spain |

UNF |

- |

FG15 |

FG20 |

FG25 |

FG30 |

FG35 |

- |

|

Belgium |

NBN 830-01 |

FGG10 |

FGG15 |

FGG20 |

FGG25 |

FGG30 |

FGG35 |

FGG40 |

|

Australia |

AS 1830 |

- |

T150 |

T220 |

T260 |

T300 |

T350 |

T400 |

|

Sweden |

SS 14 01 |

O110 |

O115 |

O120 |

O125 |

O130 |

O135 |

O140 |

|

Norway |

NS11 100 |

SJG100 |

SJG150 |

SJG200 |

SJG250 |

SJG300 |

SJG350 |

- |

|

Min. Tensile Strength (Mpa) |

100 |

150 |

200 |

250 |

300 |

350 |

- |

|

Grey iron applications:

The following is the common application for each degree of grey cast iron for your reference.

G100:

For small loads, the friction and wear no special requirements for important castings, such as protective cover, cover, oil pan, hand wheels, frame, floor, hammer, small handle, etc.

G150:

Under moderate load of castings, such as the base, frame, box, knife, bed, bearing seat, table, wheels, cover, pump, valve, pipe, flywheel, motor blocks and other

G200 and G250:

Requirements withstand greater load and a certain degree of tightness or corrosion resistance of the more important castings such as cylinder, gear, base, flywheels, bed, cylinder block, cylinder liner, piston, gear box, brake wheel, coupling Plate, medium pressure valve, etc.

G300 and G350

Under high load, wear and high air tightness important castings, such as heavy machine tools, shears, presses, automatic lathe bed, frame, frame, high-pressure hydraulic parts, piston rings, force larger gear, Cams, bushings, large engine crankshaft, cylinder block, cylinder liner, cylinder head, etc.

Samples of cast iron products:

Cast iron backwater valve 6" and jointing

|

|

|

Cast iron pan

|

|

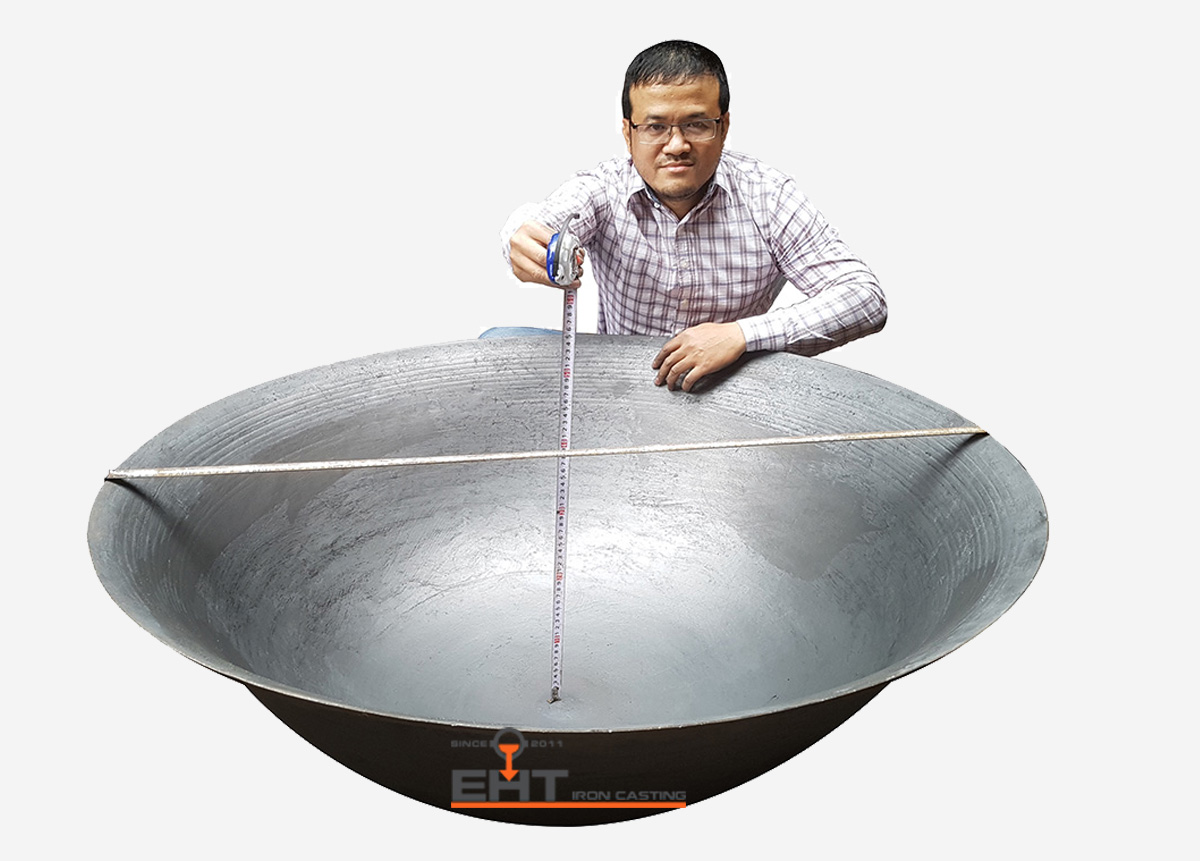

Cast iron bowls

|

|

Cast iron manhole cover

|

|